- Pretreatment Section of the Oil Mill Plant

- Pressing Section for Oil Mill Plant

- Solvent Extraction Plant

- Oil Refining Plant

- Filling Section of the Oil Mill Plant

- Oil Modification Plant

- Seed Processing Plant

- Small Oil Production Line

- oil press

- YZS-30 Sesame Oil Pressing Machine

- YZS-68 Soya Oil Press

- YZS-80 Canola Oil Press

- YZS-95 Sunflower Seed Oil Press

- YZS-100 Oil Expeller Press

- YZS-120 Oil Pressing Machinery

- YZS-130 Screw Oil Press

- YZS-160 Oil Seed Press

- YZS-80A Combined Oil Press

- YZS-95A Automatic Oil Press Machine

- YZS-100A Automatic Oil Expeller

- Steel Silo

- Face Mask

- Oil Production Process 5S Groundnut

- Physical Refining Process Of The Edible Oil Refining Machine

- Cottonseed Oil Processing Equipment

- Something About Sunflower Oil Extraction Machine

- Something About Soybean Oil Refining Machine

- Something About Edible Oil Solvent Extraction

- Rice Bran Oil Extraction Equipment

- Soybean Oil Refining Equipment

Dry Fractionation

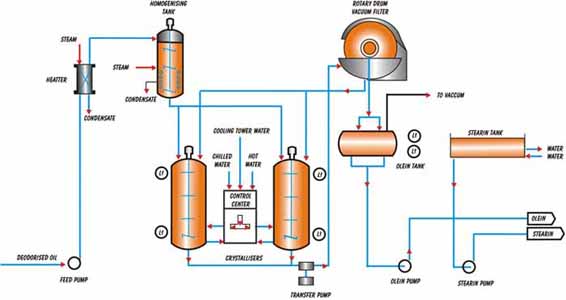

Fractionation is a physical modification process. It is widely used in the oil modificaton plant. There is no chemical change to the products. And of course in the process of dry fractionation, there is no use of costly or hazardous chemical additives, no yield loss and no contamination of the oils. Because it produces no effluent, the dry fractionation process is also environmentally friendly.

Dry fractionation, also known as crystallization from the melt, is fractional crystallization in its simplest form. The features of the technology allow it to be used for the production of commodity fats. Dry fractionation has long been regarded as an unpredictable, tedious and labor-intensive process. However, the relatively cheap dry fractionation technique has evolved to the modification technology of the 21st century, as without additives, polluting effluents or post-refinement involved, the sustainability and safety of the process is second to none.

The production of oils from oilseeds and oil-rich fruits such as the olive and palm almost certainly pre-dates biblical times, but oil modification processes are generally not more than one hundred years old. The widespread use of the three oil modification processes—hydrogenation, interesterification and fractionation—in the twentieth century extended the range of applications of the triglyceride oils almost beyond recognition. These processes principally serve the purpose of modifying the melting properties of oils and fats in order to improve their functional properties in specific applications, but the processes are also used to improve the stability of the oils and fats thus processed.

Dry Fractionation

Main Features & Advantages of Dry Fractionation

- Combines all operations, and monitors from a fully automated centralized control station.

- Easy to operate, requires minimum supervision.Good flexibility. Wide range of process applications possible.

- Feedstock can be crude, semi refined or fully refined palm oil.

- Suitable for both single or double fractionation.

-

Minimum operating costs:

- Low consumption of utilities.

- Low maintenance costs.

- No oil losses.

- No pollution problems. -

Product quality.

- Good crystallization repeatability to yield consistent product quality.

- High olein yields.

- Low olein cloud point, with improved low temperature stability; cloud point as low as 2 °C with an iodine value of 65.0 possible.