Solvent Extraction of Oil Seeds

When refers to solvent extraction of oil seeds, a common method used to remove the oil from the oilseeds is solvent extraction. Existing solvent extraction methods use large volumes of solvent (typically several hundred milliliters) and long extraction times (8–16 h) to remove the oil from the seeds. Once the oil is removed, the weight percent of oil in the seeds can be determined, and the composition of the oils can be studied.

Solvent Extraction of Oil Seeds

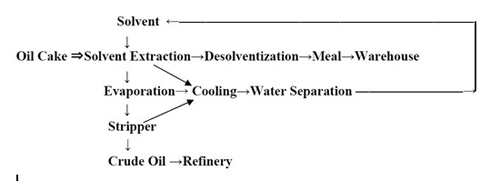

There is a variety of manufacturing methods of manufacture associated with the large range of sources. However a number of key steps are typically always undertaken. Coarse extraneous matter (wood, stones, metal) are first removed with sieves, cyclones, magnets, etc. Fine impurities (e.g. plant residues, dust, sand) are then removed by vibrating sieves, wind sifters, etc. The husks and hulls of some seeds (e.g. soya, sunflower) are removed, and the seeds are then cracked, followed by air classification, to expose the “meats” of the raw material. The meats are conditioned or dried to a required moisture level (typically 9-10%) and rolled into flakes which releases oil and improves subsequent extraction.

ASE is a relatively new extraction technique that uses elevated temperature and pressure to expedite the removal of analytes from various matrices. It is accepted by the U.S. EPA as Method 3545 for environmental samples, and it has been applied to other sample extraction areas. ASE can be used to extract a 10-g sample in about 14 min with a total solvent consumption of approximately 16 mL.

The procedures described in this application note apply to the determination of oil content in oilseeds. The oil content is determined by collecting the extracts in preweighed vials, evaporating the solvent with a nitrogen stream and reweighing the vials.

KMEC – Your forever partner for the engineering and supplying of solvent extraction of oil seeds. Active in the field of solvent extraction of oil seeds for many years, KMEC has built plants of solvent extraction of oil seeds worldwide for the capacity range of 100 to 4,000 t/d, apart from numerous small units with processing capacities below 100 t/d.

Based on the rich experience and a continuous presence in the market, KMEC solvent extraction technology has been countinuously developed to meet specific customer's needs. We are solvent extraction of oil seeds expert, We have rich experience of manufacturing and exporting solvent extraction of oil seeds, Our clients are very satisfied with our solvent extraction plant for various oil seeds. We give the best service and we offer the most competitive prices. If you prefer to know more info, please don't hesitate to contact us, we are always at your service!