Products

Useful Links

Latest News

Mar 20, 2013

Mar 20, 2013

Oct 22, 2012

Sep 26, 2012

Sep 03, 2012

Understanding How Crude Oil Is Processed

Home > Useful Links >

Crude oil is among some of the most common sources of energy all across the world. Certainly, you have asked yourself how crude oil is processed, right? Generally, crude oil is processed in a complicated type of distillation process. To understand this process clearly, let us look at an example here. You must be familiar with gasoline or motor oil, or both. In case you pour gasoline on to the ground, is vaporizes at the lowest temperatures while motor oil may take a little longer. This is because of their differed boiling points and that is the principle behind crude oil processing.

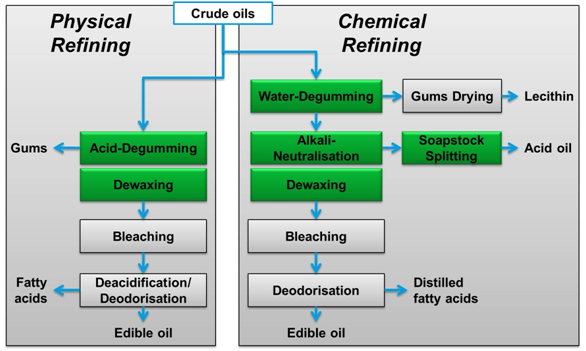

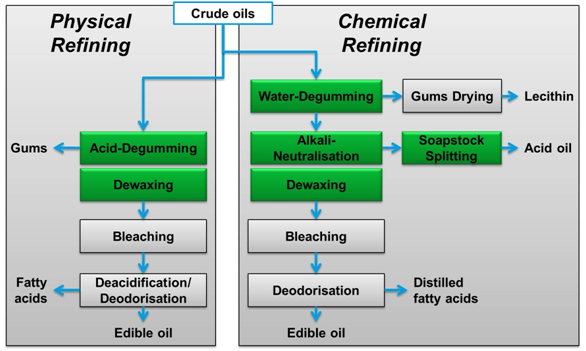

The first feature of crude oil processing is distillation. After the crude oil is super-heated to temperatures up to 1120F, it is pumped into the distillation column. Here, the gaseous crude oil rises within the column, cooling into different types of oils and then condensing into a liquid that is then pushed from the column. The refinement bit follows. After the liquids have been pumped from the distilling column, they are passed through four types of equipment of refining. These equipments use chemicals and heat to refine the particular liquids further, resulting to purer chemicals.

That is not all about how crude oil is processed. Depending on the quality of the crude oil desired, the processing may include other activities. Blending is one activity among the end processes. For instance, gasoline is blended for a number of treated components resulting from various units of processing. Quality control is the final step, especially in all modern crude oil laboratories. This involves technicians conducting the quality checks. In gasoline, they involve the checking of proper octane rating. If necessary, performance boosters are added to the crude oil products.

That is not all about how crude oil is processed. Depending on the quality of the crude oil desired, the processing may include other activities. Blending is one activity among the end processes. For instance, gasoline is blended for a number of treated components resulting from various units of processing. Quality control is the final step, especially in all modern crude oil laboratories. This involves technicians conducting the quality checks. In gasoline, they involve the checking of proper octane rating. If necessary, performance boosters are added to the crude oil products.

Henan Kingman M&E Complete Plant Co., Ltd © 2011

Email:info@kmecomp.com