Soybean Oil Processing

In the soybean oil processing, you usually should cut the soybeans into flakes and then put them in a percolation extractors and immerged with a solvent. After removing the hexane, the extracted flakes only contain about 1% of soybean oil and is used as livestock meal or to produce food products such as soy protein. The hexane is separated from the soybean oil in evaporators. The evaporated hexane is recovered and returned to the extraction process. The hexane free crude soybean oil is then further refined.

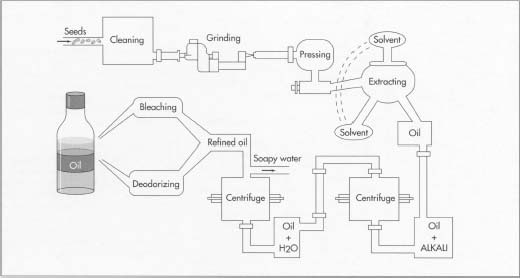

Oil refining is another important process in soybean oil processing. The oil obtained from pressing or solvent extraction process always contains impurities such as phospholipids, FFA, pigment, off-flavor and other impurities. In order to make the oil edible, the impurities must be taken out; such a process is called “Oil Refining”. The oil-insoluble material are removed with filtration and the soluble materials is removed with different processes including degumming (removing of phosphatides), alkali refining (washing with alkaline solution to remove free fatty acids, colorants, insoluble matter and gums) and bleaching (with activated earth or activated carbon to remove colour and other impurities.

Soybean Oil Processing Plant

The soybean oil plant is a version of seed processing plant. In order to process quality soybean oil, a series of soybean oil processing machinery will be involved. The process of the soybean oil plant typically consists of five steps: oilseed handling/elevator operations, preparation of soybeans for solvent extraction, solvent extraction and oil desolventizing, flake desolventizing, and oil refining. The following pictures shows some of the soybean oil processing plants.

Soybean oil is an edible oil with a light and clean flavor that is commonly used for cooking. The oil is 60% polyunsaturated fat and 24% monounsaturated fat, according to the National Soybean Research Laboratory, making it a heart-healthy oil.

Soybean oil is extracted by several methods. Commercially, chemical extraction using hexane is common, with this method, the oil yield is typically aroud 19% (the dreg oil in meal is about 1%). Another method is mechanical pressing, with this method, however, the oil yield is always around 13% (the dreg oil in cake is about 7%). cold pressing the beans using a small hand operated seed oil press is the most available method for extracting the virgin soybean oil at home.

Our soybean oil processing plant are designed and manufactured with advanced oil processing technology and the oil processing machinery are all of good quality. We guarantee the great service and most competitive price! Welcome to contact us, we are always at your service!