Winterization

Winterization is a separation process which allows the removal of higher melting point crystalized parts (waxes or triglyceride) that are responsible for the turbidity of some edible oils in the winter or after refrigeration. In the case of sunflower oil or other vegetable oils, this process can also be called "oil dewaxing".

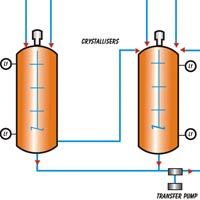

Principle of Winterization

Winterization is a thermomechanical separation process where componenet triglycerides of fat and oil are crystallized from a melt. The fractionation is accomplished via partial solidification of certain triglyceride componenets which are separated from the oil by filtration. The triglycerides found in oils and fats have a complex nature because a single triglyceride may have one, two or three fatty acids either the same or different in any of the possible configurations.Most of the triglyceride tend to assume the average characteristics of their constitutent fatty acids.

The wax content od oil depends on the oil content of oil seeds and the process technology. Generally speaking, for sunflower seeds with an oil comtent of at least 40%, the wax content is 0.65-2.33%, when processing decorticated seed. A good winterization process should also be able to dewax oil from undecorization of dcacidification.

For good operation, it is necessary to remove the gums before winterization. The percentage oif gums in the oil influences the formation and stability of formed crystals.

Another factor in dewaxing is optimum oil temperature. For good crystallization and maturation, the oils is cooled to 6-7C. The viscosity of the oil does not allow an acceptable filtration rate at this temperature.