palm oil refining

KMEC is one of the specialists in the field of oil refining. With years' experirence of designing,manufacturing and instaling complete oil refining plant as well as offering variety of oil refining equipment for different types of oilseeds, we can now provide state of the art palm oil refining technology for all of our clients, at the same time, we also apply the advanced technique to our equipment.

Palm oil contains several saturated and unsaturated fats in the forms of glyceryl laurate (0.1%, saturated), myristate (1%, saturated), palmitate (44%, saturated), stearate (5%, saturated), oleate (39%, monounsaturated), linoleate (10%, polyunsaturated), and linolenate (0.3%, polyunsaturated). Its increasing use in the commercial food industry in other parts of the world is buoyed by its lower cost[8] and the high oxidative stability (saturation) of the refined product when used for frying.

Palm Oil Refining Process

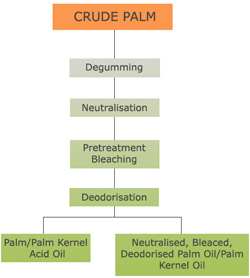

General speaking, the palm oil refining route is quite identical. Two routes are taken to process crude palm oil into refined oils, they are chemical refining and physical refining. The methods differ basically in the way the fatty acids are removed from the oil.

Physical refining, which eliminates the need for an effluent plant for the soap stock, involves subjecting the oil to steam distillation under higher temperature and vacuum for removal of the free fatty acids. The physical refining is used to remove the free fatty acids. The refining of physical plant is practiced to subject the oil to steam distillation. The aim of palm oil refining is therefore to convert the crude oil to quality edible oil by removing objectionable impurities to the desired levels in the most efficient manner. This also means that, where possible, losses in the desirable component are kept minimal.

Palm oils consist mainly of glycerides and, like other oils in their crude form, small and variable portions of non-glyceride components as well. In order to render the oils to an edible form, some of these non-glycerides need to be either removed or reduced to acceptable levels.

In term of solubility study – glycerides are of two broad types: oil insoluble and oil soluble. The insoluble impurities consisting of fruit fibres, nut shells and free moisture mainly, are readily removed. The oil soluble non-glycerides which include free fatty acids, phospholipids, trace metals, carotenoids, tocopherols or tocotrienols, oxidation products and sterols are more difficult to remove and thus, the oil needs to undergo various stages of refining. Not all of the above non-glyceride components are undesirable. The tocopherols and tocotrienols not only help to protect the oil from oxidation, which is detrimental to flavour and keep ability of the finished oil, but also have nutritional attributes, a- and b-carotene, the major constituents of carotenoids, are precursors of vitamin A. The other impurities generally are detrimental to the oil’s flavour, odour, colour and keep ability and thus influence the oil’s usefulness.

With an inherent desire to be the best in the palm oil refining field, we have come out with new developments and oil refining machinery that have not just improve the quality of the existing machines but also introduce new models in this market. Write to us if you are interested.