Oil Processing Process

Oilseeds preparation, oil extraction, oil degumming, oil bleaching, oil deoderization, and oil hydrogenation are all the main processes of oil processing process. In the entire oil processing, a lot of oil processing equipment will be used in differnt oil processing stages. Natural compounds are changed by the effect of heat and chemical. This causes either the conversion or removal of the nutrients. According to the manufacturers, nutrients are required to be removed for stopping spoilage and enhancing its shelf life.

Oil Processing Process

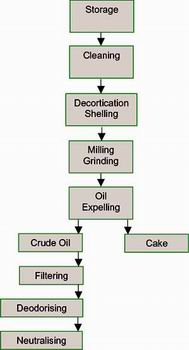

Oil processing process starts with oil seeds preparation, then goes into the pressing section then the oil will be extracted in the solvent extraction plant, later the extracted oil should be sent to the refining plant for further processing. However, sometimes oil modification plant is necessary to get high quality edible oils.

Detailed Oil Processing Process

Oil processing starts with oil seeds preparation. Heating and dehulling, followed by chopping or grinding, to break the cell walls, freeing the oil to make the penetration of solvents into the cells easier. This is accomplished by rolling or flaking, but it is still not enough to release all of the oil. Therefore, a thermal or conditioning step is required. In addition, all oil seeds have enzymes that can influence quality. During processing, the object is to deactivate these enzymes early by means of heat. For example, with canola or rapeseed, the enzyme myrosinase can influence quality because it catalyses hydroysis of glucosinolates to give glucose, sulphate, isothiocyanates, oxazolinine thiones, and other compounds. Some of these compounds act as a catalyst poison during hydrogenation of oil for margarine production.

Oil extraction in the oil processing process means extract oils from oilseeds is accomplished by mechanically pressing or by mixing with such gasoline-like solvents as hexane and heptane (which are lung irritants and nerve depressants). If the chemical extraction method is used, the oil is extremely flammable, and some factories have been known to blow up or catch on fire. Later, the oils are steam heated to evaporate the solvents at temperatures around 300°F. Most of the solvents are evaporated, but not all. The primary objective of this step is to produce a clean, crude oil product. Be aware that, at this stage, the oil can now be bottled and sold as "unrefined oil" in health food stores and delicatessens. Oil designated for more refining goes through more processing procedures. After being mashed and cooked for up to two hours at varying temperatures, depending on the seed type, mechanically pressed seeds are subject to additional heating during the "auger" process, where the average temperature reaches about 120°C (248°F) with higher temperatures and pressures producing more oil. At this temperature, however, oil reacts with oxygen more than 100 times faster than at room temperature, producing fatty acid damage. In some cases, after mechanical pressing, the oil is filtered and sold as unrefined oil, but more often, the oil undergoes further refining.

Oil degumming in the oil processing process is a treatment of crude oils and water, salt solutions, dilute acids, or alkalis used in order to remove phosphates, waxes, and other impurities. Caustic soda, (often sodium hydroxide -- commonly known as Drano -- or a mixture of sodium hydroxide and sodium carbonate) is one such substance used to remove free fatty acids that can cause rancidity and decreases the quality of the oil. Alkali solutions combine with the free fatty acids to form soaps and also helps to remove toxic substances that are naturally present in many plants. Temperatures again have reached 75°C (167°F). At this stage, the oil still has its pigmentaion of red, yellow, or greenish hue, which is also deemed undesireable. Degumming converts the phosphatides to hydrated gums which are insoluble in oil and readily separated as sludge. The hydrated gums are vacuum dried for crude lecithin processing. This process also involves the addition of phosphoric acid and water at temperatures of 60°C (140°F).

Bleaching oils is necessary because they have a strong yellow or reddish pigment that is considered undesirable. In the bleaching process, oils are heated to temperatures of 175°-225°C, for about 4 hours, and mixed with a type of clay substance that will absorb the unwanted pigment. Most of the spent clay is then filtered from the oil. During this phase, some of the polyunsaturated fatty acids may undergo oxidation and toxic peroxides, forming conjugated fatty acids. Deoderization is done through pressurized steam distillation at temperatures of 240°-270°C (464-518°F) for 30 to 60 minutes, which removes undesirable odors and tastes from the oil.

Note: When temperatures go above 150°C (302°F), unsaturated fatty acids become mutagenic. Above 160°C(320°F), trans fatty acids begin to form. Above 200°C (392°F), trans fatty acids multiply substantially, and, above 220°C, the rate of trans fatty acids explodes.

Deoderizing in the oil processing process reduces the content of many other substances, including residues, toxins, and products of oxidation formed during the bleaching stage, as well as removing sulphur, monoglycerides, sterols, beta carotene, and tocopherols (Vitamin E). The oil is now tasteless and cannot be distinguished from other oils derived from seeds or plants. At this point, despite all of the heating involved, the oils can still be sold as "cold-pressed" since there is no accepted definition of the term. Preservatives are added such as synthetic antioxidants, BHT (butylated hydroxytoluene), BHA (butylated hydroxyanisole, propyl gallate, TBHQ (teriary butyhydroquinone), citric acid, or methylsilicone. A defoamer may also be added to prevent turbidity when refrigerated.

Hydrogenation: After all this, oils not designated for sale, go on to more processing in the form of hydrogenation to make margarines, shortenings, and shortening oils. The hydrogenation of oils converts liquid oils into hard fats by adding hydrogen to the fat molecule. Oils can be hydrogenated to varying degrees, depending on the hardness. The most common forms are shortening, margarines, and the partially hydrogenated fats used for frying and in processed foods. These fats are desirable for its melting point, allowing for high temperature cooking and frying.

Hydrogenation involves the artificial saturation of fully refined oils to harden them into spreadable products. All oils sold in supermarkets and convenience stores are processed in the above manner. "ALL" includes safflower, walnut, sunflower, corn, grape seed, soybean, sesame, rice bran, canola, almond, peanut, avocado, and others including blends. Olive oil is the only oil sold on supermarket shelves that is not heated above 150°C. However, it is a poor source of essential fatty acids, containing on average 10% LA and 0.5% LNA.

After the refining process above, oils are put under pressure, using hydrogen gas at temperatures of 120-210°C (248-410°F) in the presence of a metal catalyst (nickel, platinum, or copper) for six to eight hours. A nickel catalyst is actually 50% nickel and 50% aluminum. Remnants of both metals remain in the final products of hydrogenated or partially hydrogenated goods. During complete hydrogenation, all double bonds are saturated with hydrogen. This means there are no unsaturated fatty acids, no w6's, and no w3's. In some partially hydrogenated margarines, the trans fatty acid content can be more than 60%. Partially hydrogenated oils are found in French fries (37.4%), candies (38.6%), and bakery products (33.5%). A completely hydrogenated oil is now a hard fat containing no essential fatty acid activity, causing a nation-wide deficiency of the essential fatty acids.

We are expert of oil processing. We have rich experience of manufacturing and exporting oil processing plant as well as large selection of various oil processing machinery. Write to us if you want to more more about our oil processing process. We are always at your service.