Oil Processing

We are expert of oil processing and related oil processing machinery. We have rich experience of designing, manufacturing and exporting complete oil processing plants as well as large selection of various oil processing machines for differen processing purposes.We also offer state of the art oil processing technology for all of our clients.

Oil Processing

Oil processing means processing of oils and fats from vegetable sources. Vegetable oils and fats are mainly used for human consumption, however it is also used as animal feed both for medicinal purposes and certain technical applications. The main oil processing process are as follows.

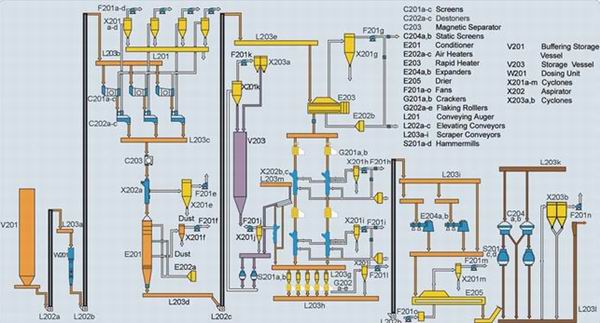

- The beans are properly cleaned into seed cleaner, before they enter into the de-stoner. The beans are cleaned for removing unwanted impurities & dust.

- Cleaned seeds then enter the De-stoner, where the stones are separated by a vibrating action.

- After de-stoning is completed, the seeds enter the Seed Cracker where these are broken into two or three pieces.

- The cracked seeds are then conditioned in the Conditioner (Cooker) by using steam.

- The conditioned seeds are then flaked in the Flaker machine.

- Finally, the flaked material is forwarded to the Solvent Extraction Plant.

Oil Processing Technology

We offer advanced oil processing technology. The oils and fats are extracted from different types of seeds, fruit and nuts. The preparation of oilseeds including husking, cleaning, crushing, and conditioning. The extraction processes are generally mechanical or including use solvent such as hexane. After the process of solvent extraction, the crude oil is separated and the solvent will be evaporated and recovered. Residues are conditioned (for example, dried) and are reprocessed to yield by-products such as animal feed. Then the crude oils need to be refined. Oil refining including degumming, neutralization, bleaching, deodorization, and further refining.

We are committed to provide good after sales services to all our esteemed clients. We believe that nomatter what the field is, quality and service are always the most important factors.So anytime you are interested in oil processing or oil processing technology, please feel free to contact us!